Service Quality Management

“The first car is sold by the salesman, every subsequent one by the service”. True to this bon mot, the service quality achieved in the network of a car manufacturer is of central importance for customer satisfaction, customer loyalty as well as turnover and profit – especially against the background of the often high profitability of after-sales for dealers and manufacturers.

From the definition of service quality to the measurement concept

In order to be able to manage and thus continuously improve the service quality provided at the “point of service” from a manufacturer’s point of view, this first requires a definition and operationalisation. The prevailing MSR model is based on the two dimensions of service outcome and service experience – i.e. technical quality and customer experience at the points of contact.

When developing measurement and control concepts, it is usually necessary, on the one hand, to define the model with its concrete requirements for the measurement variables and, on the other hand, to identify and qualify, above all, the suitable KPIs or raw data already available in the company.

In this project, one of the main requirements was to define the measurement sensors in such a way that they could only be operated with centrally retrievable data – in order to map the performance in terms of service quality at the levels of the group, the subsidiaries and the individual car dealerships and workshops.

Typical indicators in such a model for repair quality in the narrower sense are, on the one hand, indicators such as repeat repair rate, technical protocols up to the customer’s confirmation in the usual follow-up surveys that all work has been carried out without any complaints.

The time component is also collected via suitable constructs – from parts availability and delivery speed to lead time.

Depending on the manufacturer, there are also suitable measurement instruments for the structures and processes relevant to service quality, such as documentation obligations for warranty work or the fulfilment of touchpoints before the customer (e.g. submission of a cost estimate, offer of a replacement vehicle).

In addition to the above-mentioned objective or objectifiable quality criteria, comprehensive models should also take into account the subjective customer perception, in the course of which it is often possible to fall back on existing ongoing customer surveys.

Implementation of a measurement system

The basis of the measurement system is the above-mentioned operationalisation according to theoretical requirements (e.g. MECE “Mutually-exclusive-collectively-exhaustive) as well as practical feasibility (especially data availability and acceptance).

This example deals with the development of a measurement and control system for the service quality of an automobile manufacturer in the brand-affiliated workshop network.

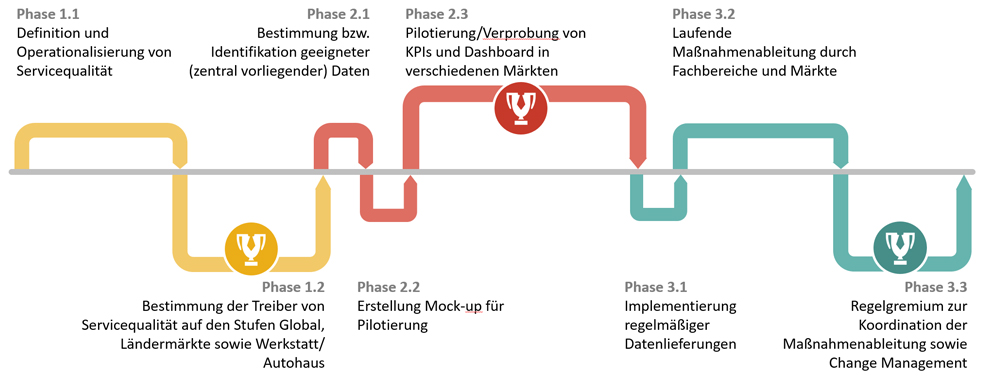

To create a living steering tool, the figures must be permanently available in a dashboard. This allows units (depending on the level of rights) to access the current figures. However, the path to this should be gradual:

- Preparation and consolidation of the figures

- Creation of mock-ups / speedboats to test the KPIs in the individual units

- Transfer to a continuous system

- Embedding in structured exchange with the units and initiating a continuous optimisation process

This approach has proven successful in the past. The path via mock-ups is crucial for successful implementation. During this period, the focus is on the discussion of content, and the technical implementation takes place downstream, when all relevant stakeholders have already been involved. In this way, a prototype can be completed after just a few weeks without incurring large costs for IT integration. The parallel coordination process then enables a smooth transfer into the running operation.

Implementation of service quality management in the company

However, a measurement system or reporting only unfolds its potential when it is used effectively to control and manage a company. This is where the outlined model for service quality has a special effect, as it not only shows potential for improvement in the form of benchmarks or targets at the “point of service”, but is also able to do so for the other levels and actors at group level (e.g. poor lead times can be due to poor delivery capabilities of parts at national or central level). In this way, there is a great benefit in regularly bringing all responsible actors together in a corresponding governance approach in order to identify fields of action, define suitable measures and monitor their effectiveness through measurement (e.g. all market managers and representatives of the relevant central departments come together in the course of quarterly reports for a regular quarterly exchange and ensure improvements in their respective areas of responsibility). The improvement of service quality thus develops an additional dynamic and this continuously and sustainably.